Like most things in life, proper care and maintenance can help improve and elongate the life of your restaurant equipment. For steamers and combi ovens, this includes using deliming products and regularly changing your water filter cartridges.

Before you place an order for a new filtration system with your local Hobart Service technician, let's review the basics and benefits.

Replacing Water Filter Benefits

- Improved Equipment Performance – Regularly replacing the water filter can prevent the buildup of minerals and scale, which can clog the internal components and reduce the efficiency of the steamer or oven. Clean filters ensure optimal steam production and consistent cooking temperatures.

- Extended Equipment Lifespan – By preventing mineral buildup, regular filter changes can prolong the life of the equipment, reducing the need for repairs or replacements due to wear and tear or malfunctioning parts.

- Better Food Quality – Clean water filters ensure that the steam is pure, which can improve the taste and quality of the food being cooked. It prevents off-flavors and ensures that the food retains its natural flavor and nutrients.

- Compliance and Safety – In many cases, regular maintenance, including filter replacement, is required for compliance with health and safety regulations. It ensures that the equipment is functioning safely and reduces the risk of breakdowns during operation.

How Steam is Made Matters

Although the benefit of filtered water for steam cooking is universal, some steam cooking equipment is more susceptible to severe performance issues than others. The easiest way to understand the risk that the equipment in your operation faces is to learn the difference between Boilerless and Generator-Based Steam Cooking.

-

Boilerless - These steamers utilize water delivered manually or automatically within the cooking cavity. The cooking temperature turns the water to steam, which condensates on the steamer cavity walls as a closed system. This steamer type is best for batch cooking operations, where the steamer door is not opened until the food batch is done. The method to delime is using white vinegar or Scale Release (Part Number 854893-13) in the steamer cavity. One bag, mixed with 2 gallons of warm filtered water, will treat a C24EO3 or C24EO5 steamer. Spray cavity walls with solution, and pouring remaining solution into cavity well. Run steamer for 5 minutes, and let soak for 30 to 60 minutes before draining and rinsing thoroughly with warm clean water. Wipe all surfaces, including door gasket & glass with clean moistened cloth with filtered water. Leave the door open overnight to vent cavity and to extend life of gasket.

-

Generator-Based - These steamers have a sealed steam generator outside the cooking cavity. Heating elements in the generator are submersed in water for efficiency, and steam created is injected into the cooking cavity. This steamer type is the best option for continuous steam cooking operations, where the door is opened repeatedly as food is placed and removed on-demand; referred to as à la carte operations.

Vulcan Generator-Based Steamers (EA Series, ET Series, & GA Series)

FILTRATION FOR BOILERLESS COMBI OVENS

Vulcan offers a variety of field-installed water treatment options for all TCM, ABC, and MiniJet™ Combis. We offer three kinds of water filtration based on customer water quality to meet the equipment water spec requirements.

- Hollow Carbon Filter System – cleans water by catching particles and pulling out harmful chemicals like chlorine, along with lead, PCBs, radon, pesticides and herbicides, other types of bacteria by using a special kind of carbon, offering minimum filtration.

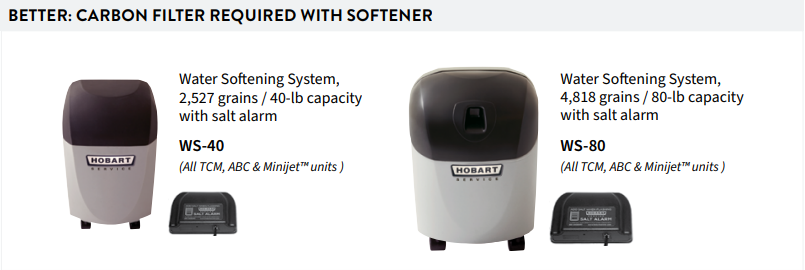

- Water Softening System With Required Carbon Filter – removes unwanted chemicals and particles while also removing calcium, magnesium, and iron to soften the water.

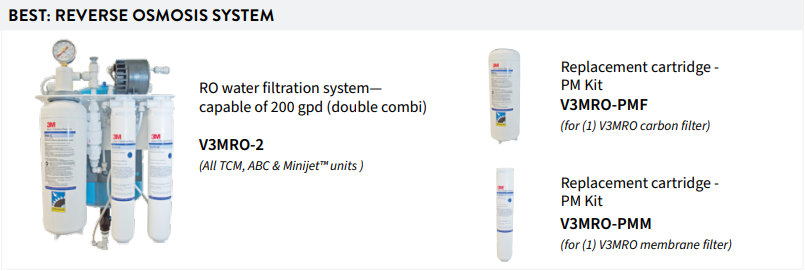

- Reverse Osmosis System – water is forced through a semi-permeable membrane that filters out a large majority of contaminants, including particles, bacteria, and chemicals. The process requires water pressure to push the water through the membrane, leaving impurities behind.

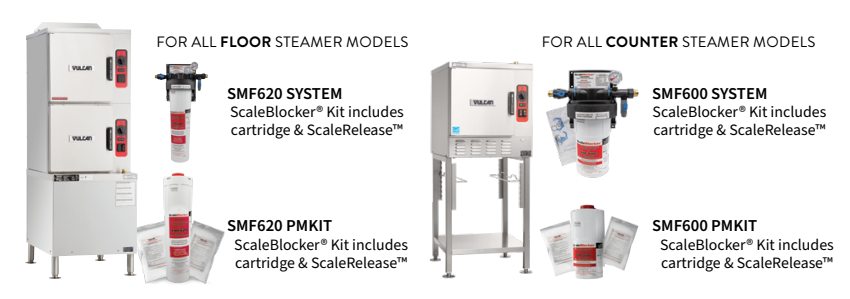

ScaleBlocker® Water Filtration System for generator-based steamers

A safe and economical way to maintain your Vulcan Steamer is by using Vulcan’s ScaleBlocker® water system. ScaleBlocker® minimizes lime scale buildup and corrosion, which can dramatically affect the operation of your steamer and result in downtime or service calls.

The steam components on all Vulcan Steamers installed with the ScaleBlocker® water system have an extended second year limited extended warranty, subject to operators keeping on top of maintenance, registering the original filter and replacing it every 6 months, deliming each month, and keeping a proper maintenance log [See full Warranty Statement for all terms and conditions].

In essence, replacing the water filters in-line for steamers and combi ovens is crucial for maintaining the equipment's performance, ensuring food quality, and prolonging the life of the machine, while adhering to health and safety standards. Contact your Hobart Service technician and schedule replacing your water filter today!